Ensuring safe operations

Our sensors are integrated with these autonomous vehicles, to continuously collect data about their position and orientation, allowing for real-time adjustments and strategic planning based on insights.

Autonomous systems can adapt to various terrains and environments, and their deployment can be scaled up based on operational needs.

Increasing efficiency

Industrial logistics’ autonomous systems operate continuously without fatigue, optimizing time and resources in material transport and other logistics operations. They reduce human involvement in dangerous environments, lowering accident rates and improving overall safety in industries like mining or construction.

Automated conveyor belts, sorters, and cranes move items between storage areas, loading docks, and production lines, improving the flow of goods and reducing manual labor. Automation speeds up processes, such as order picking, packing, and shipping, enabling businesses to handle larger volumes of goods with fewer delays.

Key benefits of these solutions include process optimization, increased efficiency, and greater safety for employees.

Delivering real-time positioning

Our real-time positioning systems provide operators with location-relevant data and helps make the logistics process faster and smoother.

Not only can a locating system help increase productivity, but it also enables automated real-time decision-making and identification of hidden costs.

Indoor positioning in industry and logistics makes the locations of goods and employees visible and allows for analysis, coordination, and optimization of manufacturing and logistics processes.

Solutions for industrial logistics

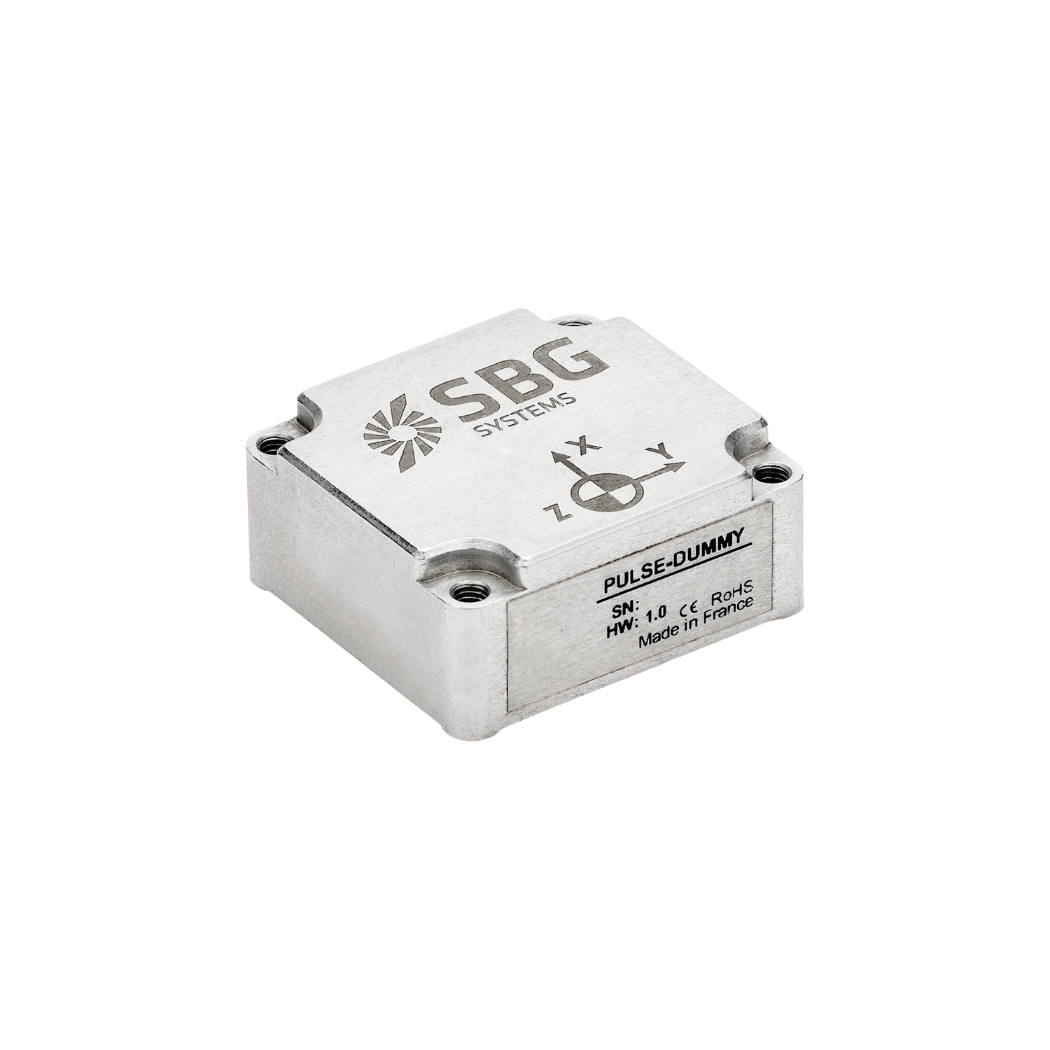

Discover how our sensors integrate seamlessly with industrial logistics platforms to deliver reliable performance, even in the most challenging conditions.

Industrial applications brochure

Get our brochure delivered straight to your inbox!

Explore more industrial applications

Discover how our advanced inertial navigation systems and motion sensors are transforming a wide range of autonomous vehicles applications. From land-based robots to underwater vehicles, our solutions enable precise, reliable performance in diverse and challenging environments. Explore how we support the evolution of autonomous technologies with our cutting-edge solutions.

Do you have questions?

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

What is an automated guided vehicle?

An automated guided vehicle, or AGV, is a type of mobile robot used in industrial applications to transport materials and products within a facility without human intervention.

AGVs are guided by various technologies such as magnetic strips, lasers, inertial sensors, or cameras that allow them to navigate predetermined paths and avoid obstacles.They are commonly used in industries like manufacturing, warehousing, and logistics to automate tasks like moving pallets, raw materials, or finished goods.

AGVs improve efficiency, reduce labor costs, and enhance safety by performing repetitive tasks autonomously. They play a key role in modern automated industrial systems.