Fueling Duke Aero’s success in rocketries

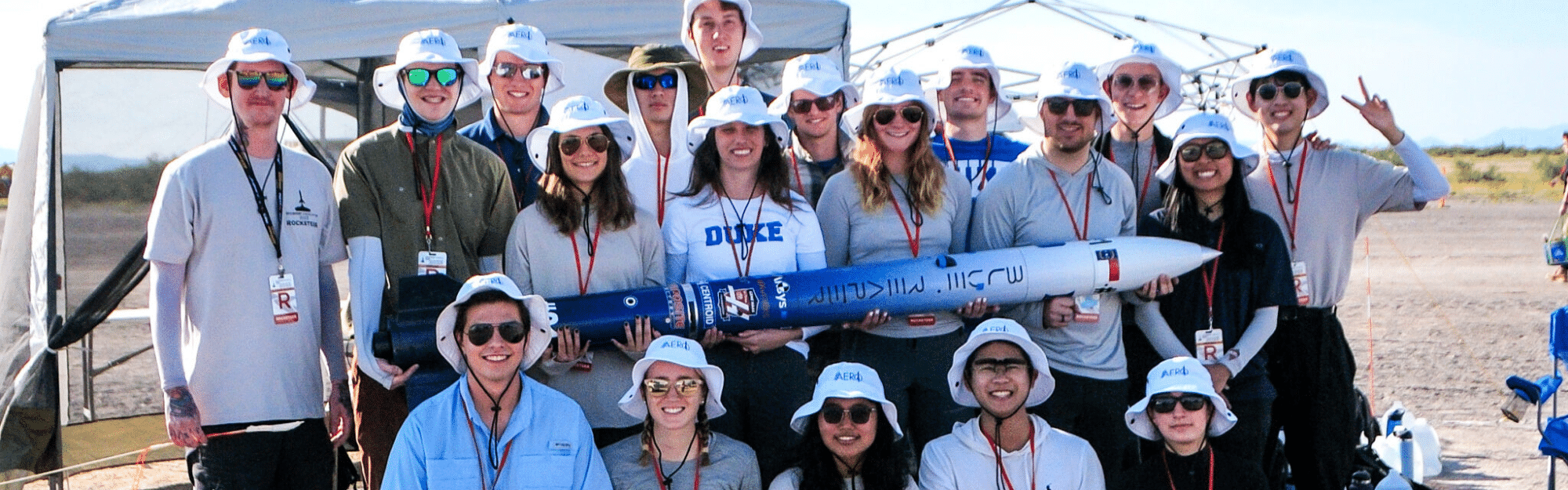

Empowering ambition: our sponsorship helps Duke AERO successfully launch their rocket.

“We were seeking a high quality IMU or INS to provide data for a new airbrake system onboard our rocket. As a high-speed vehicle with large accelerations and rapidly changing physical parameters, we needed a sensor with fast polling rates and accurate data in a very short span of time.” | Josh Kramer, team lead, Duke AERO.

Duke AERO is an ambitious team with a passion for aerospace and engineering. Their objective is to provide students with a platform to work on real projects and gain exposure to the aerospace industry.

By participating in competitions like the Spaceport America Cup and fostering research projects, Duke AERO aims to nurture an innovative environment for students.

Meet Duke AERO’s project, Duke University’s high-powered rocketry team. They embarked on a challenging mission to build the Blue Reaper rocket for the prestigious Spaceport America Cup in New Mexico.

To enhance their rocket’s performance and safety, they sought a reliable Inertial Measurement Unit (IMU) for their airbrake system. After thorough research, they approached us for a potential sponsorship.

The quest for perfect IMU

In their pursuit of excellence, team Duke AERO identified the need for a high-quality IMU that could deliver accurate data rapidly and withstand the intense physical parameters experienced during rocket flights.

They recognized that SBG Systems had previously sponsored another team at the competition, providing them with an INS for their airbrake control solution. Intrigued by our reputation, they decided to explore the possibility of a partnership.

First impression

During their initial contact with us, the Duke AERO team had a positive experience. The young team reached out to Jack Mawson, who is the head of sales for North American region.

This initial interaction left a lasting impression for us and for Duke AERO’s team it ignited an interest in the potential collaboration.

This is what Josh Kramer, from team Duke AERO, had to say after meeting Jack, “Our initial call was extremely informative, and our contact (at SBG Systems), Jack Mawson, gave us a great rundown of the company and its products. He was excited at the prospect of helping our team, and we had a great first impression”.

Apart from the favorable first impression, Duke AERO was impressed by our suite of navigational sensor products, which seemed ideal for integrating into their rocket’s electronic systems.

Our commitment to sponsoring collegiate teams and engaging with students also resonated with Duke AERO’s values.

They recognized that SBG Systems had previously sponsored another team at the competition, providing them with an INS for their airbrake control solution.

Integration

After carefully analyzing the student team’s requirement, Jack suggested Ellipse-D as a perfect fit for their control system. The team was satisfied by our IMU’s compatibility with their control systems and were impressed with the Software Center’s ability to make corrections to the data with ease.

Commenting on the performance of our product, Josh said, “the Ellipse IMU/INS units are incredibly high-performance devices, and the live flight data was used in conjunction with other sensors and microcontrollers to control in real time a precision variable-drag air-braking system. The SBG product was intuitive to use and the corresponding SBG Center software made for easy adjustments”.

The Software Center has real time preset configurations and can operate in different modes. There is no specific rocketry application, but they found the airplane mode to be the most suitable for their use. The rated acceleration or vibration capabilities of the Ellipse units were perfect for their needs and performed excellently in a high-power rocket launch.

However, there were challenges during the integration. The technical support team timely addressed every question that team had regarding the hardware and resolved the faulty cable issue.

Impact of Duke Aero’s sponsorship

We at SBG encourage innovation and nurture young talent. SBG sponsors numerous student-led projects, demonstrating our commitment to educating and developing future industry leaders.

We empower students to explore their passion for aerospace and engineering in real-world scenarios through sponsorships and technological assistance.

Our high-quality sensors empowered the development of their airbrake module, enhancing the rocket’s performance and safety.

The partnership also provided valuable exposure to advanced aerospace technology, benefiting the team’s members both academically and professionally.

Duke Aero’s successful launch

The launch was successful, and we couldn’t be happier. May the Duke AERO team reach new heights and expand their horizons as they continue their journey in aerospace excellence.

We wholeheartedly support their endeavors and eagerly await the positive impact they will have on the future of aerospace.

Ellipse-D

The Ellipse-D is an inertial navigation system integrating a dual antenna and dual frequency RTK GNSS that is compatible with our Post-Processing software Qinertia.

Designed for robotic and geospatial applications, it can fuse Odometer input with Pulse or CAN OBDII for enhanced dead-reckoning accuracy.

Request a quote for Ellipse-D

Do you have questions?

Welcome to our FAQ section! Here, you’ll find answers to the most common questions about the applications we showcase. If you don’t find what you’re looking for, feel free to contact us directly!

What is a payload?

A payload refers to any equipment, device, or material that a vehicle (drone, vessel …) carries to perform its intended purpose beyond the basic functions. The payload is separate from the components required for the vehicle operation, such as its motors, battery, and frame.

Examples of Payloads:

- Cameras: high-resolution cameras, thermal imaging cameras…

- Sensors: LiDAR, hyperspectral sensors, chemical sensors…

- Communication equipment: radios, signal repeaters…

- Scientific instruments: weather sensors, air samplers…

- Other specialized equipment

What is the difference between IMU and INS?

The difference between an Inertial Measurement Unit (IMU) and an Inertial Navigation System (INS) lies in their functionality and complexity.

An IMU (inertial measuring unit) provides raw data on the vehicle’s linear acceleration and angular velocity, measured by accelerometers and gyroscopes. It supplies information on roll, pitch, yaw, and motion, but does not compute position or navigation data. The IMU is specifically designed to relay essential data about movement and orientation for external processing to determine position or velocity.

On the other hand, an INS (inertial navigation system) combines IMU data with advanced algorithms to calculate a vehicle’s position, velocity, and orientation over time. It incorporates navigation algorithms like Kalman filtering for sensor fusion and integration. An INS supplies real-time navigation data, including position, velocity, and orientation, without relying on external positioning systems like GNSS.

This navigation system is typically utilized in applications that require comprehensive navigation solutions, particularly in GNSS-denied environments, such as military UAVs, ships, and submarines.

Does INS accept inputs from external aiding sensors?

Inertial Navigation Systems from our company accept inputs from external aiding sensors, such as air data sensors, magnetometers, Odometers, DVL and other.

This integration makes the INS highly versatile and reliable, especially in GNSS-denied environments.

These external sensors enhance the overall performance and accuracy of the INS by providing complementary data.