OEM Ellipse-N Single antenna Inertial Navigation System

OEM Ellipse-N is part of a compact, high-performance GNSS-aided SMD inertial navigation systems, engineered for precise orientation, position, and heave measurements in a miniature form factor.

This advanced solution integrates an Inertial Measurement Unit (IMU) with a dual-band, quad-constellation GNSS receiver, leveraging cutting-edge sensor fusion technology to deliver reliable performance, even in demanding environments. Equipped with single antenna heading, it ensures exceptional accuracy and stability for applications requiring precise heading, including in static conditions.

Discover all features and applications of OEM Ellipse-N.

Specifications

Motion & navigation performance

1.2 m Single point position vertical

1.5 m RTK position horizontal

0.01 m + 1 ppm RTK position vertical

0.02 m + 1 ppm PPK position horizontal

0.01 m + 0.5 ppm PPK position vertical

0.02 m + 1 ppm Single point roll/pitch

0.1 ° RTK roll/pitch

0.05 ° PPK roll/pitch

0.03 ° Single point heading

0.2 ° RTK heading

0.2 ° PPK heading

0.1 °

Navigation features

Single and dual GNSS antenna Real time heave accuracy

5 cm or 5 % of swell Real time heave wave period

0 to 20 s Real time heave mode

Automatic adjustment Delayed heave accuracy

2 cm or 2.5 % Delayed heave wave period

0 to 40 s

Motion profiles

Car, automotive, train/railway, truck, two wheelers, heavy machinery, pedestrian, backpack, off road Air

Plane, helicopters, aircraft, UAV Marine

Surface vessels, underwater vehicles, marine survey, marine & harsh marine

GNSS performance

Internal single antenna Frequency band

Dual frequency GNSS features

SBAS, RTK, RAW GPS signals

L1C/A, L2C Galileo signals

E1, E5b Glonass signals

L1OF, L2OF Beidou signals

B1/B2 GNSS time to first fix

< 24 s Jamming & Spoofing

Advanced mitigation & indicators, OSNMA ready

Magnetometer performance

50 Gauss Scale factor stability (%)

0.5 % Noise (mGauss)

3 mGauss Bias stability (mGauss)

1 mGauss Resolution (mGauss)

1.5 mGauss Sampling rate (Hz)

100 Hz Bandwidth (Hz)

22 Hz

Environmental specifications & operating range

Aluminum, conductive surface finish Operating temperature

-40 °C to 78 °C Vibrations

8g RMS – 20Hz to 2 kHz Shocks (operational)

100g 6ms, half-sine wave Shocks (non-operational)

500g 0.1ms, half-sine wave MTBF (computed)

218 000 hours Compliant with

MIL-STD-810G

Interfaces

GNSS, RTCM, odometer, DVL, external magnetometer Output protocols

NMEA, Binary sbgECom, TSS, KVH, Dolog Input protocols

NMEA, Novatel, Septentrio, u-blox, PD6, Teledyne Wayfinder, Nortek Output rate

200 Hz, 1,000 Hz (IMU data) Serial ports

RS-232/422 up to 2Mbps: up to 3 inputs/outputs CAN

1x CAN 2.0 A/B, up to 1 Mbps Sync OUT

PPS, trigger up to 200 Hz – 1 output Sync IN

PPS, event marker up to 1 kHz – 2 inputs

Mechanical & electrical specifications

2.5 to 5.5 VDC Power consumption

600 mW Antenna power

3.0 VDC – max 30 mA per antenna | Gain: 17 – 50 dB Weight (g)

17 g Dimensions (LxWxH)

29.5 x 25.5 x 16 mm

Timing specifications

< 200 ns PPS accuracy

< 1 µs (jitter < 1 µs) Drift In dead reckoning

1 ppm

OEM Ellipse-N applications

OEM Ellipse-N gives you precision and versatility, bringing advanced GNSS-aided inertial navigation to a broad spectrum of applications.

From autonomous vehicles and UAVs to robotics and marine vessels, it ensures exceptional accuracy, reliability, and real-time performance.

Our expertise covers aerospace, defense, robotics, and more, delivering unmatched quality and dependability to our partners.

Discover all applications.

OEM Ellipse-N datasheet

Get all the sensor features and specifications delivered straight to your inbox!

Compare with other products

Compare our most advanced inertial range of sensors for navigation, motion, and heave sensing.

Full specifications can be found in the Hardware Manual available upon request.

| Single point position horizontal | Single point position horizontal 1.2 m | Single point position horizontal 1.2 m | Single point position horizontal 1.2 m | Single point position horizontal 1.2 m |

|---|---|---|---|---|

| Single point roll/pitch | Single point roll/pitch 0.1 ° | Single point roll/pitch 0.1 ° | Single point roll/pitch 0.03 ° | Single point roll/pitch 0.03 ° |

| Single point heading | Single point heading 0.2 ° | Single point heading 0.2 ° | Single point heading 0.08 ° | Single point heading 0.06 ° |

| GNSS receiver | GNSS receiver Internal single antenna | GNSS receiver Internal dual antenna | GNSS receiver Internal dual antenna | GNSS receiver Internal dual antenna |

| Datalogger | Datalogger – | Datalogger – | Datalogger 8 GB or 48 h @ 200 Hz | Datalogger 8 GB or 48 h @ 200 Hz |

| Ethernet | Ethernet – | Ethernet – | Ethernet Full duplex (10/100 base-T), PTP / NTP, NTRIP, web interface, FTP | Ethernet Full duplex (10/100 base-T), PTP / NTP, NTRIP, web interface, FTP |

| Weight (g) | Weight (g) 17 g | Weight (g) 17 g | Weight (g) 38 g | Weight (g) 76 g |

| Dimensions (LxWxH) | Dimensions (LxWxH) 29.5 x 25.5 x 16 mm | Dimensions (LxWxH) 29.5 x 25.5 x 16 mm | Dimensions (LxWxH) 50 x 37 x 23 mm | Dimensions (LxWxH) 51.5 x 78.75 x 20 mm |

Compatibility drivers and software

Documentation and resources

Our products come with comprehensive online documentation, designed to support users at every step. From installation guides to advanced configuration and troubleshooting, our clear and detailed manuals ensure smooth integration and operation.

Production process

Discover the precision and expertise behind every SBG Systems products. This following video offers an inside look at how we meticulously design, manufacture, and test our high-performance inertial navigation systems.

From advanced engineering to rigorous quality control, our production process ensures that each product meets the highest standards of reliability and accuracy.

Watch now to learn more!

Ask for a quotation

FAQ section

Welcome to our FAQ section, where we address your most pressing questions about our cutting-edge technology and its applications. Here, you’ll find comprehensive answers regarding product features, installation processes, troubleshooting tips, and best practices to maximize your experience.

Whether you’re a new user seeking guidance or an experienced professional looking for advanced insights, our FAQs are designed to provide the information you need.

Find Your Answers Here !

Does INS accept inputs from external aiding sensors?

Inertial Navigation Systems from our company accept inputs from external aiding sensors, such as air data sensors, magnetometers, Odometers, DVL and other.

This integration makes the INS highly versatile and reliable, especially in GNSS-denied environments.

These external sensors enhance the overall performance and accuracy of the INS by providing complementary data.

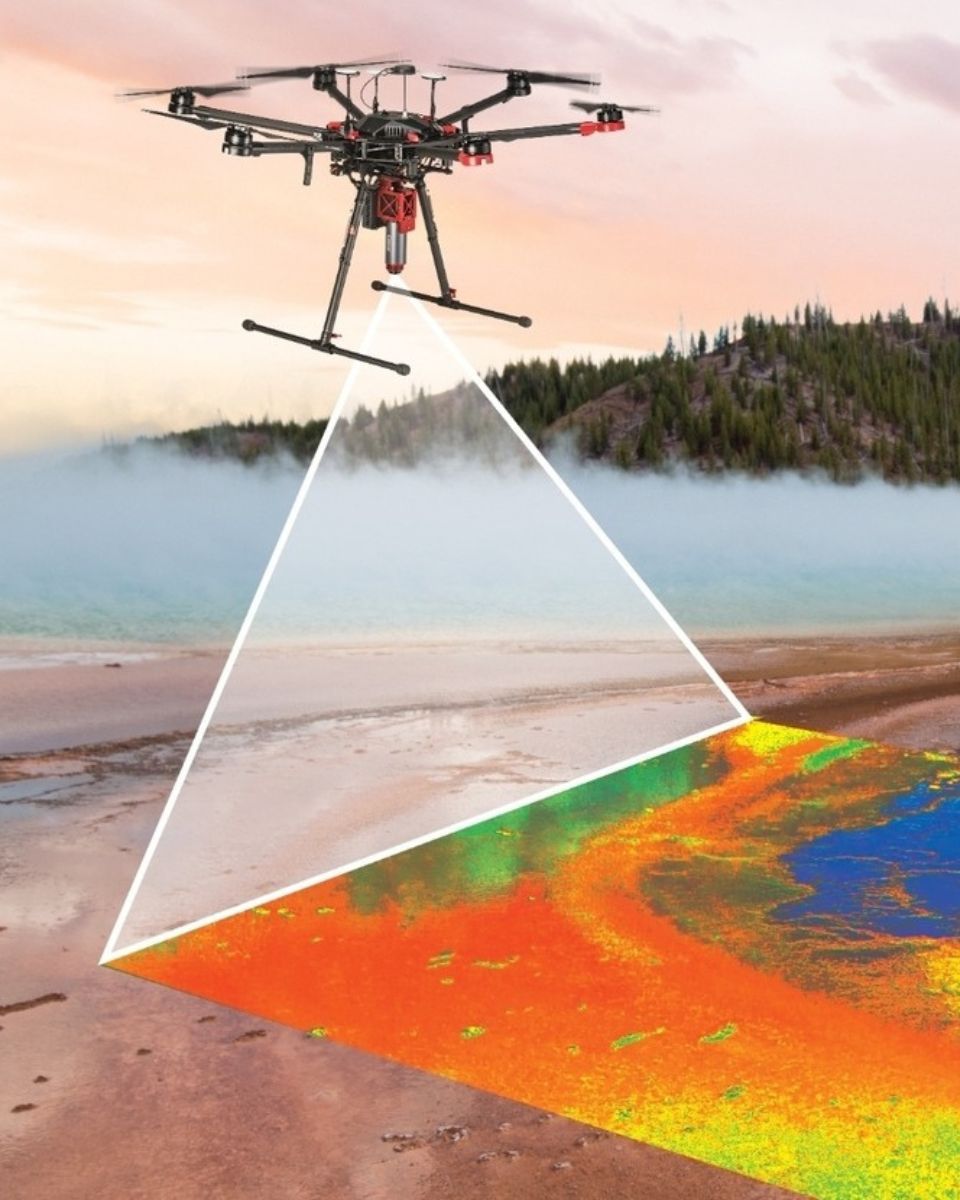

How can I combine inertial systems with a LIDAR for drone mapping?

Combining SBG Systems’ inertial systems with LiDAR for drone mapping enhances accuracy and reliability in capturing precise geospatial data.

Here’s how the integration works and how it benefits drone-based mapping:

- A remote sensing method that uses laser pulses to measure distances to the Earth’s surface, creating a detailed 3D map of the terrain or structures.

- SBG Systems’ INS combines an Inertial Measurement Unit (IMU) with GNSS data to provide accurate positioning, orientation (pitch, roll, yaw), and velocity, even in GNSS-denied environments.

SBG’s inertial system is synchronized with the LiDAR data. The INS accurately tracks the drone’s position and orientation, while the LiDAR captures the terrain or object details below.

By knowing the precise orientation of the drone, the LiDAR data can be accurately positioned in 3D space.

The GNSS component provides global positioning, while the IMU offers real-time orientation and movement data. The combination ensures that even when the GNSS signal is weak or unavailable (e.g., near tall buildings or dense forests), the INS can continue to track the drone’s path and position, allowing for consistent LiDAR mapping.

What is the difference between IMU and INS?

The difference between an Inertial Measurement Unit (IMU) and an Inertial Navigation System (INS) lies in their functionality and complexity.

An IMU (inertial measuring unit) provides raw data on the vehicle’s linear acceleration and angular velocity, measured by accelerometers and gyroscopes. It supplies information on roll, pitch, yaw, and motion, but does not compute position or navigation data. The IMU is specifically designed to relay essential data about movement and orientation for external processing to determine position or velocity.

On the other hand, an INS (inertial navigation system) combines IMU data with advanced algorithms to calculate a vehicle’s position, velocity, and orientation over time. It incorporates navigation algorithms like Kalman filtering for sensor fusion and integration. An INS supplies real-time navigation data, including position, velocity, and orientation, without relying on external positioning systems like GNSS.

This navigation system is typically utilized in applications that require comprehensive navigation solutions, particularly in GNSS-denied environments, such as military UAVs, ships, and submarines.