Apogee-A High-performance orientation and heave data solution

Apogee-A belongs to Apogee series line of high performance, MEMS based Inertial Systems which deliver exceptional orientation data in a compact package.

It includes an Inertial Measurement Unit (IMU) and runs exclusive Extended Kalman Filter (EKF) algorithms.

Discover all features and applications.

Specifications

Motion & navigation performance

0.01 ° Heading

0.02 °

Navigation features

Single and dual GNSS antenna Real time heave accuracy

5 cm or 5 % Real time heave wave period

0 to 20 s Real time heave mode

Automatic adjustment Delayed heave accuracy

2 cm or 2 % Delayed heave wave period

0 to 40 s

Motion profiles

Car, automotive, train/railway, truck, two wheelers, heavy machinery, pedestrian, backpack, off road Air

Plane, helicopters, aircraft, UAV Marine

Surface vessels, underwater vehicles, marine survey, marine & harsh marine

Accelerometer performance

± 10 g Bias in-run instability

<7 μg Random walk

0.015 m/s/√h Bandwidth

100 Hz

Gyroscope performance

± 200 °/s Bias in-run instability

<0.05 °/hr Random walk

<0.012 °/√hr Bandwidth

100 Hz

Environmental specifications & operating range

IP-68 Operating temperature

-40 °C to 71 °C Vibrations

3 g RMS – 20 Hz to 2 kHz Shocks

500 g for 0.3 ms MTBF (computed)

50 000 hours Compliant with

MIL-STD-810, EN60945

Interfaces

GNSS heading, external magnetometer Output protocols

NMEA, Binary sbgECom, TSS, Simrad, Dolog Input protocols

NMEA, Trimble, Novatel, Septentrio, Hemisphere, DVL (PD0, PD6, Teledyne, Nortel) Datalogger

8 GB or 48 h @ 200 Hz Output rate

Up to 200Hz Ethernet

Full duplex (10/100 base-T), PTP master clock, NTP, web interface, FTP, REST API Serial ports

RS-232/422 up to 921kbps : 3 outputs / 5 inputs CAN

1x CAN 2.0 A/B, up to 1 Mbps Sync OUT

PPS, trigger up to 200 Hz – 2 outputs Sync IN

PPS, event marker up to 1 kHz – 5 inputs

Mechanical & electrical specifications

9 to 36 VDC Power consumption

3 W Weight (g)

<690 g Dimensions (LxWxH)

130 mm x 100 mm x 58 mm

Apogee-A applications

Apogee-A is a high-performance AHRS solution tailored for applications demanding precise orientation and heave data.

Advanced filtering and calibration techniques ensure Apogee-A resilience against vibrations, providing dependable data in dynamic environments.

Built with advanced MEMS technology, it delivers reliable, real-time attitude and heading data in challenging conditions, making it ideal for industries where accuracy and robustness are essential.

Discover all applications.

Apogee-A datasheet

Get all the sensor features and specifications delivered straight to your inbox!

Compare Apogee-A with other products

Discover how Apogee-A stands out against our cutting-edge inertial sensors, expertly designed for navigation, motion tracking, and precise heave sensing.

Apogee-A |

||||

|---|---|---|---|---|

| Roll/Pitch | Roll/Pitch 0.01 ° | Roll/Pitch 0.1 ° | Roll/Pitch 0.1 ° | Roll/Pitch 0.02 ° |

| Heading | Heading 0.02 ° | Heading 0.8 ° Magnetic | Heading 0.8° Magnetic | Heading 0.03 ° |

| OUT protocols | OUT protocols NMEA, Binary sbgECom, TSS, Simrad, Dolog | OUT protocols NMEA, Binary sbgECom, TSS, KVH, Dolog | OUT protocols NMEA, Binary sbgECom, TSS, KVH, Dolog | OUT protocols NMEA, Binary sbgECom, TSS, Simrad, Dolog |

| IN protocols | IN protocols NMEA, Trimble, Novatel, Septentrio, Hemisphere, DVL (PD0, PD6, Teledyne, Nortel) | IN protocols – | IN protocols – | IN protocols NMEA, Binary sbgECom, Trimble, Novatel, Septentrio, Hemisphere |

| Weight (g) | Weight (g) < 690 g | Weight (g) 10 g | Weight (g) 45 g | Weight (g) 400 g |

| Dimensions (LxWxH) | Dimensions (LxWxH) 130 x 100 x 58 mm | Dimensions (LxWxH) 26.8 x 18.8 x 9.5 mm | Dimensions (LxWxH) 46 x 45 x 24 mm | Dimensions (LxWxH) 100 x 86 x 58 mm |

Compatibility

sbgCenter

sbgCenter

Apogee-A documentation & resources

Apogee-A comes with comprehensive documentation, designed to support users at every step.

From installation guides to advanced configuration and troubleshooting, our clear and detailed online documentation ensure smooth integration and operation.

Production process

Discover the know-how and expertise behind each SBG Systems products. This following video offers an inside look at how we meticulously design, manufacture, and test our high-performance inertial navigation systems.

From advanced engineering to rigorous quality control, our production process ensures that each product meets the highest standards of reliability and accuracy.

Watch now to learn more!

Ask for a quotation

FAQ section

Welcome to our FAQ section, where we address your most pressing questions about our cutting-edge technology and its applications.

Here, you’ll find comprehensive answers regarding product features, installation processes, troubleshooting tips, and best practices to maximize your experience.

Whether you’re a new user seeking guidance or an experienced professional looking for advanced insights, our FAQs are designed to provide the information you need.

Find Your Answers Here !

What is an Offshore Support Vessel?

An Offshore Support Vessel, or OSV, support offshore oil and gas exploration, production and various maritime operations.

OSVs transport supplies, equipment, and personnel to and from offshore platforms, conduct maintenance, and assist with underwater operations. They are essential for maintaining the efficiency and safety of offshore projects.

What are wave measurement sensors?

Wave measurement sensors are essential tools for understanding ocean dynamics and improving safety and efficiency in marine operations. By providing accurate and timely data on wave conditions, they help inform decisions across various sectors, from shipping and navigation to environmental conservation.

Wave buoys are floating devices equipped with sensors to measure wave parameters such as height, period, and direction.

They typically use accelerometers or gyroscopes to detect wave motion and can transmit real-time data to shore-based facilities for analysis.

What is AHC in offshore cranes?

Active Heave Compensation (AHC) in cranes is a technology used to counteract a vessel’s vertical motion caused by waves. It ensures that loads lifted or lowered by the crane remain stable and unaffected by the sea’s movement.

AHC systems are particularly critical in offshore operations, where cranes are often used to lift and lower heavy equipment, cargo, or subsea devices from vessels or platforms in dynamic sea conditions. These systems use sensors (such as accelerometers, gyroscopes, or motion reference units) to measure the vessel’s heave (vertical movement) caused by wave action.

Based on this real-time data, the crane’s AHC system automatically adjusts the winch or hoisting mechanism to counteract the heave, ensuring that the load stays at a constant position relative to the seabed or a fixed reference point. Offshore cranes typically use hydraulic or electric systems to make these precise adjustments. The crane’s winch or hoist is rapidly adjusted to lift or lower the load in sync with the vessel’s motion, effectively “canceling out” the vertical motion caused by the waves.

By stabilizing the load during lifting or lowering operations, AHC minimizes the risk of accidents, load swinging, or equipment damage. It allows for safer, more precise operations, especially during the placement of subsea structures or when handling delicate equipment.

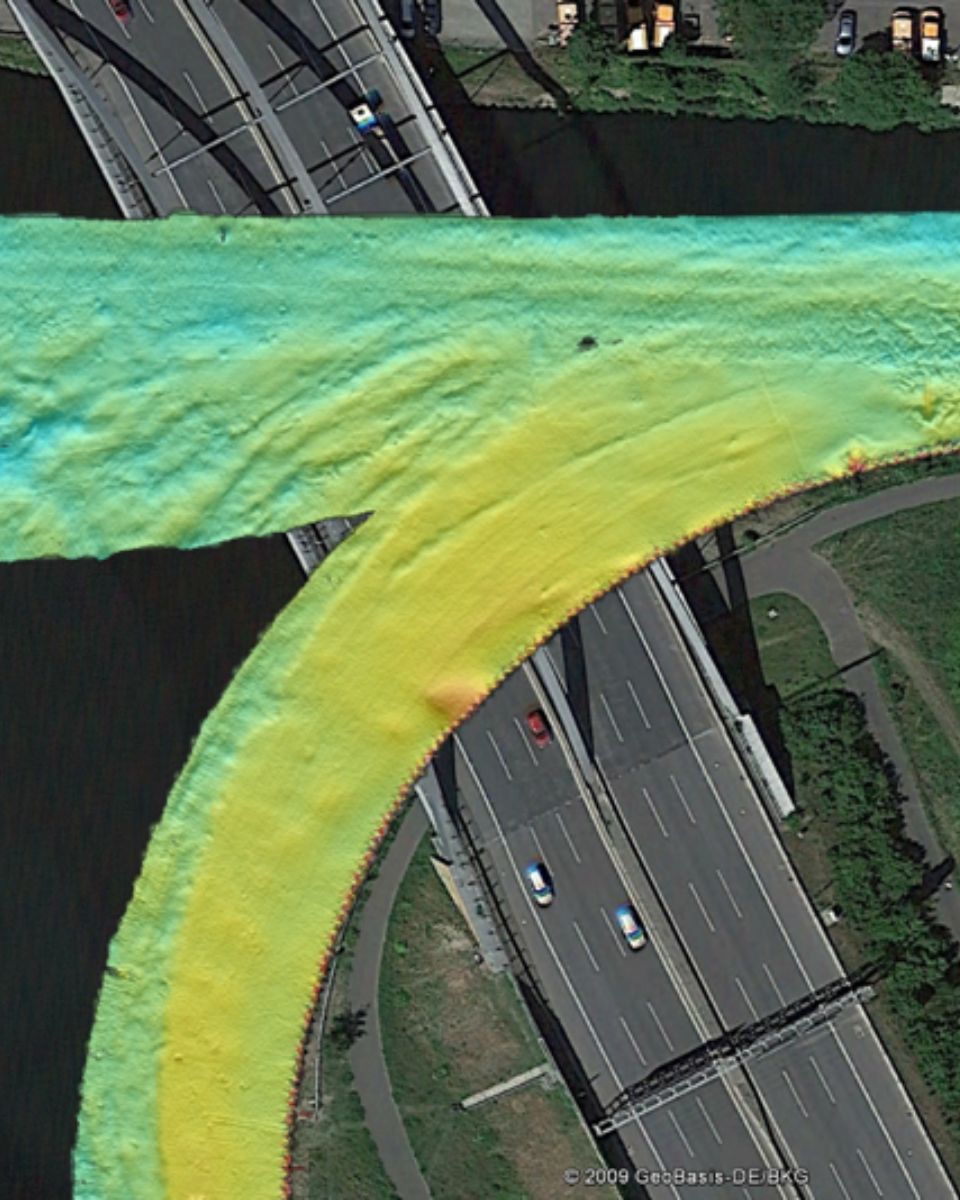

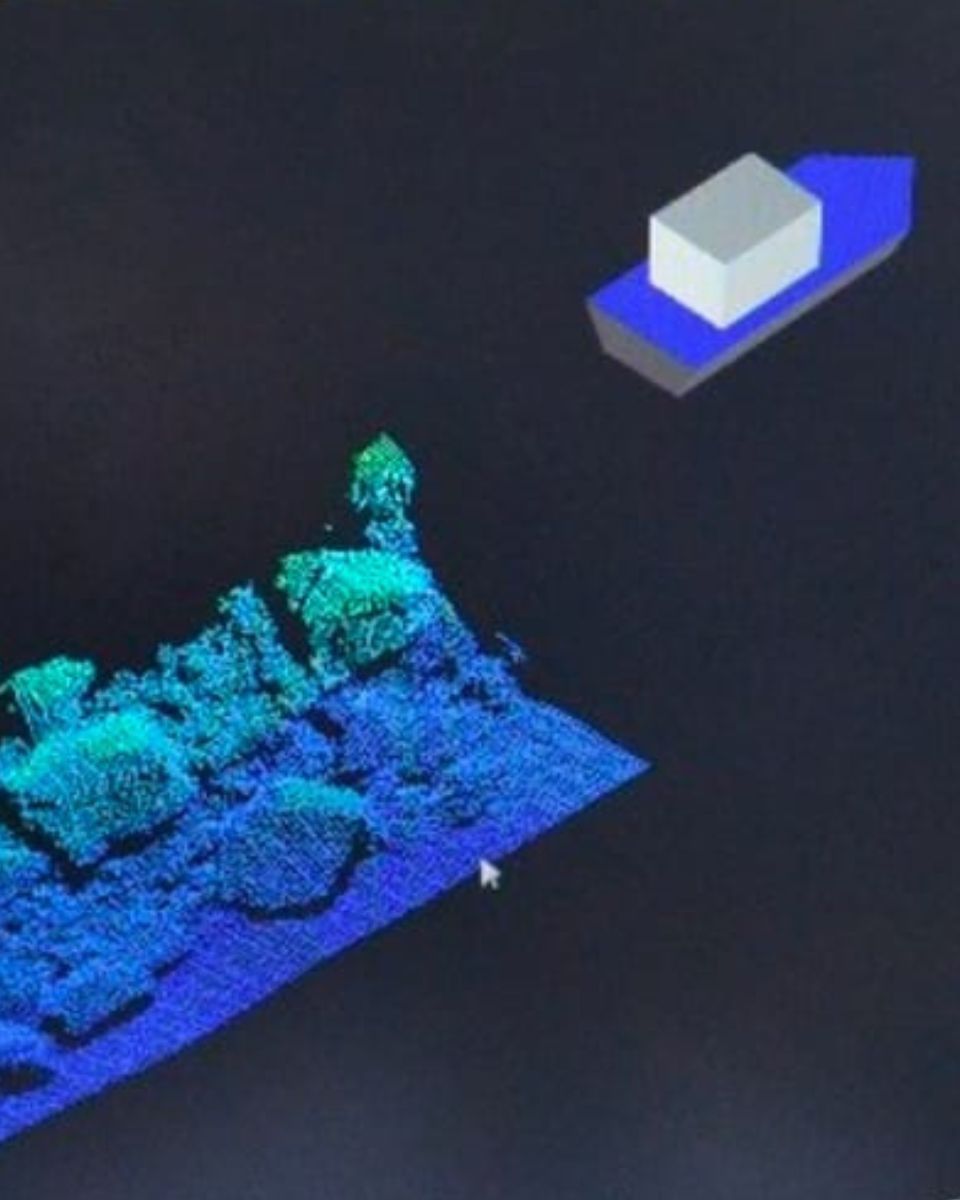

What is hydrographic surveying?

Hydrographic surveying is the process of measuring and mapping physical features of bodies of water, including oceans, rivers, lakes, and coastal areas. It involves collecting data related to the depth, shape, and contours of the seafloor (seafloor mapping), as well as the location of submerged objects, navigational hazards, and other underwater features (e.g. water trenches).

Hydrographic surveying is crucial for various applications, including navigation safety, coastal management and coastal survey, construction, and environmental monitoring.

Hydrographic surveying involves several key components, starting with bathymetry, which measures water depth and seafloor topography using sonar systems like single-beam or multi-beam echo sounders that send sound pulses to the seafloor and measure the echo’s return time.

Accurate positioning is critical, achieved using Global Navigation Satellite Systems (GNSS) and Inertial Navigation Systems (INS) to link depth measurements to precise geographic coordinates.

Additionally, water column data, such as temperature, salinity, and currents, are measured, and geophysical data is collected to detect underwater objects, obstacles, or hazards using tools like side-scan sonar and magnetometers.